In House Lab

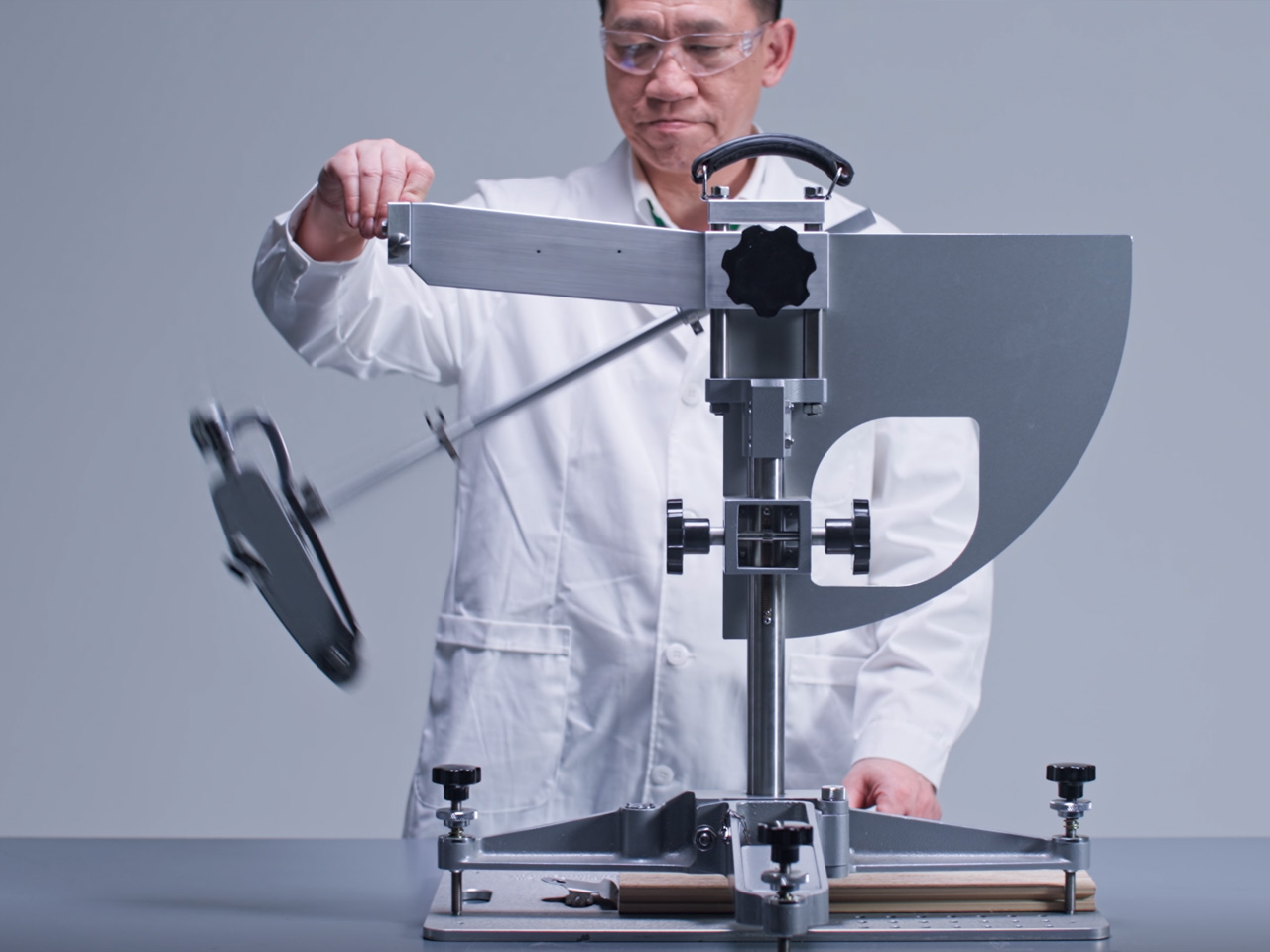

NewTechWood’s lab is where we uphold the highest standards of testing for our products. Equipped with cutting-edge technology and a team of experienced experts, we subject our products to comprehensive physical and chemical analyses, evaluating factors such as durability, dimensional stability, and impact resistance. Through continuous research and development, we strive for a continuous improvement, raising the bar for composite standards.

In House Lab

NewTechWood’s lab is where we uphold the highest standards of testing for our products. Equipped with cutting-edge technology and a team of experienced experts, we subject our products to comprehensive physical and chemical analyses, evaluating factors such as durability, dimensional stability, and impact resistance. Through continuous research and development, we strive for a continuous improvement, raising the bar for composite standards.

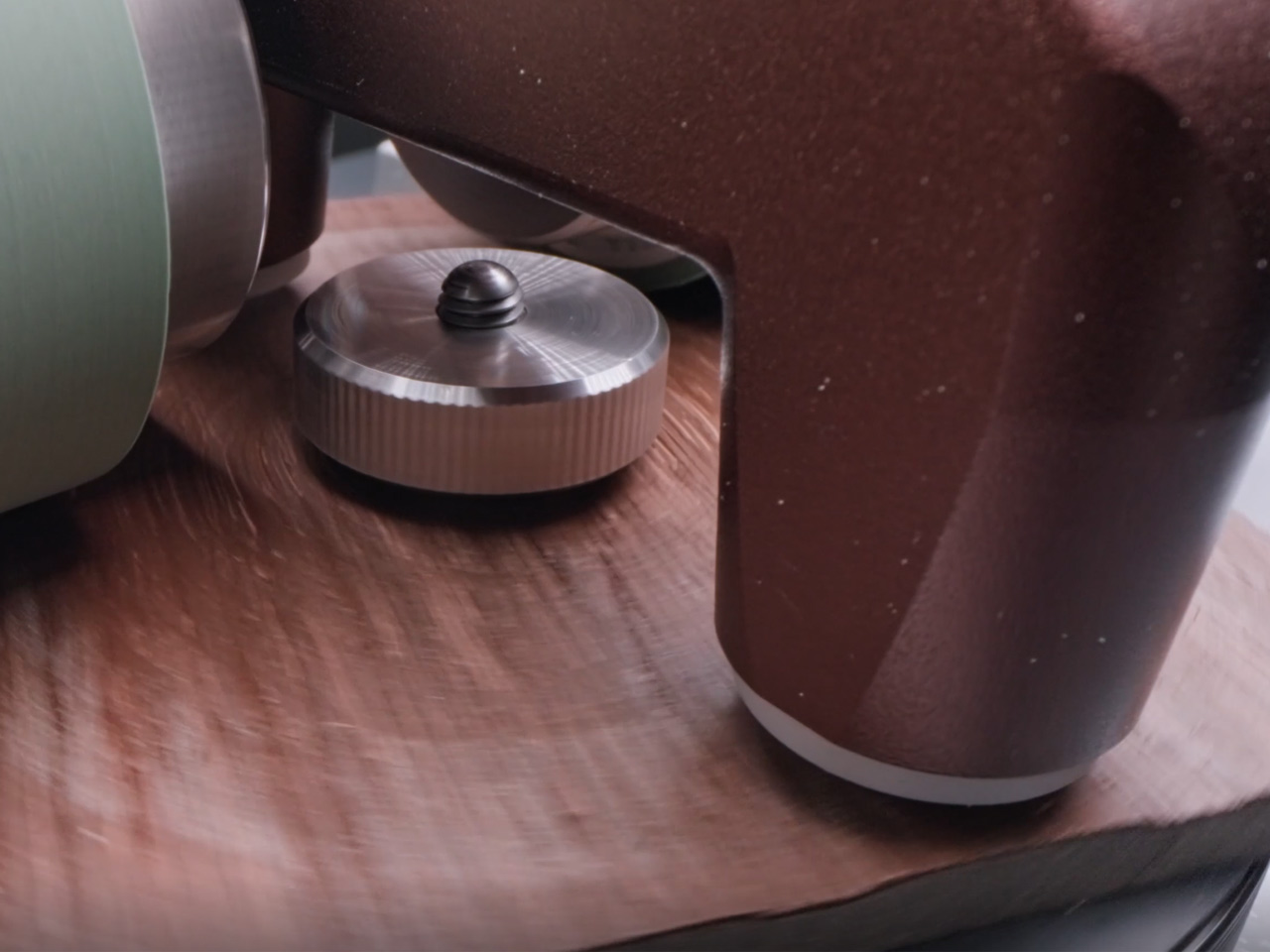

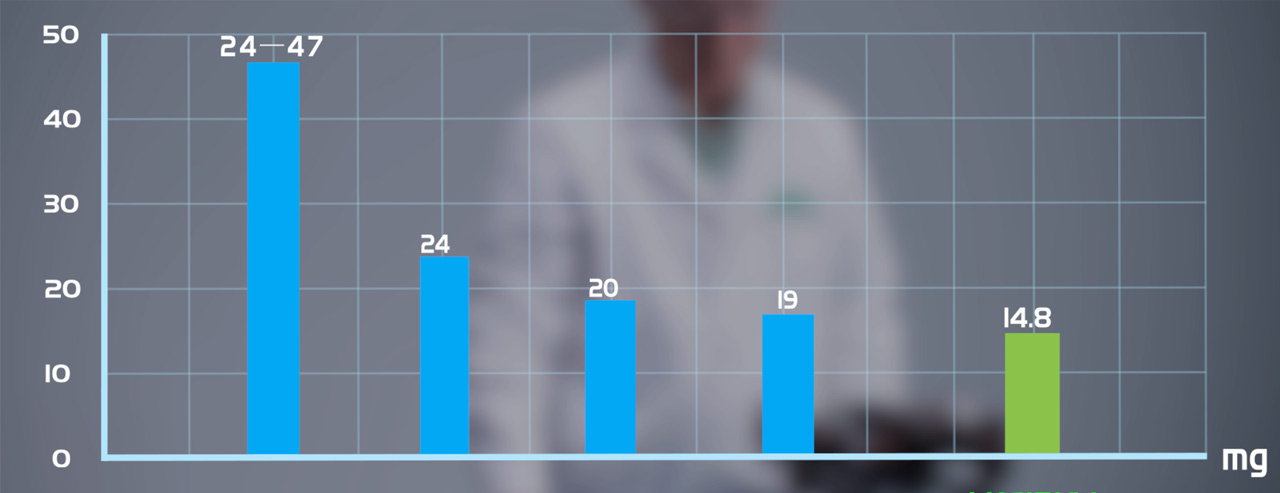

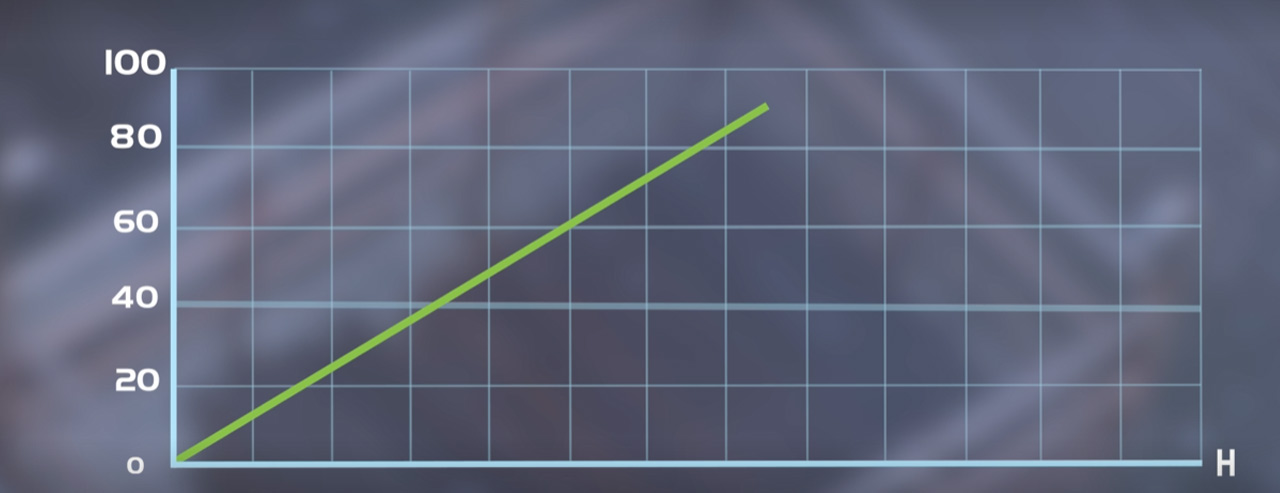

Abrasion Test

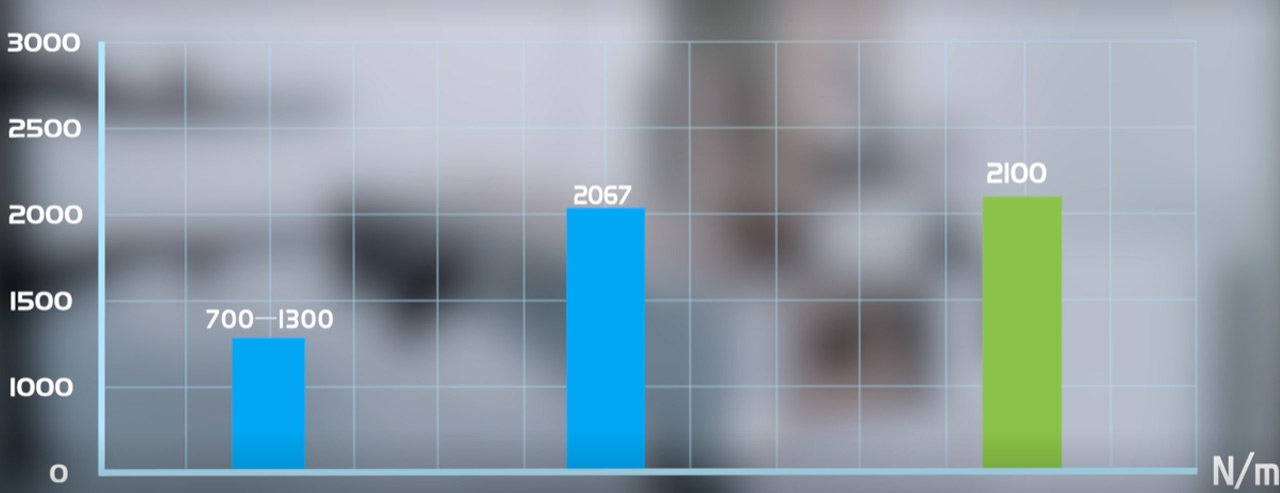

Peel Strength Test

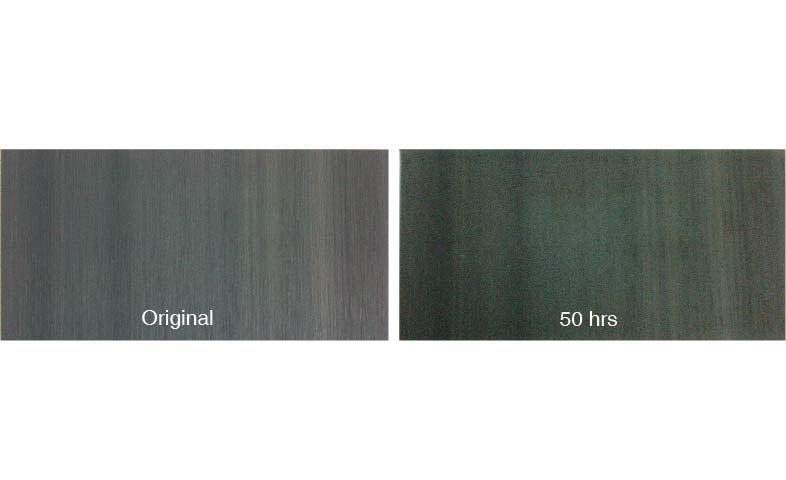

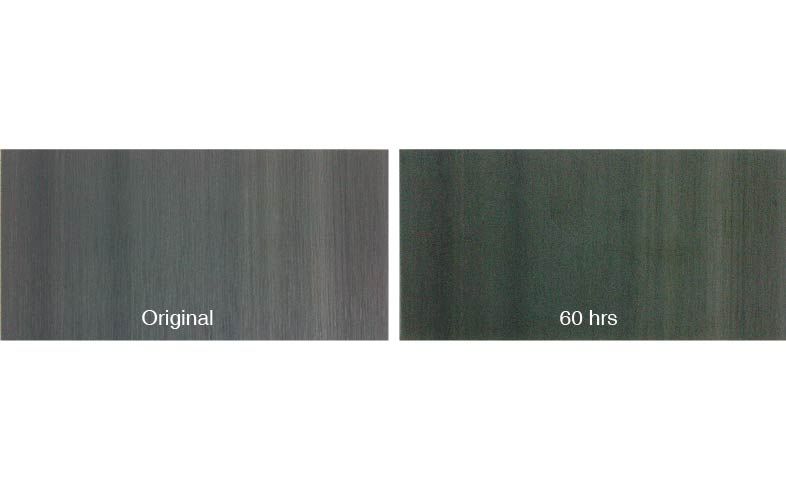

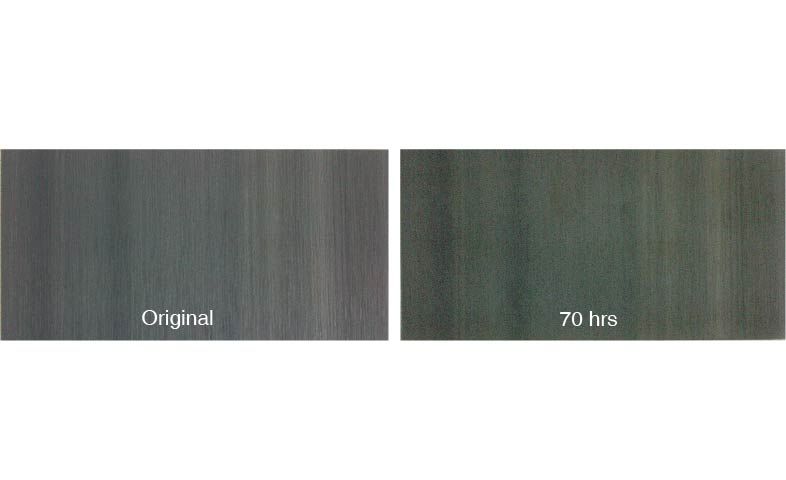

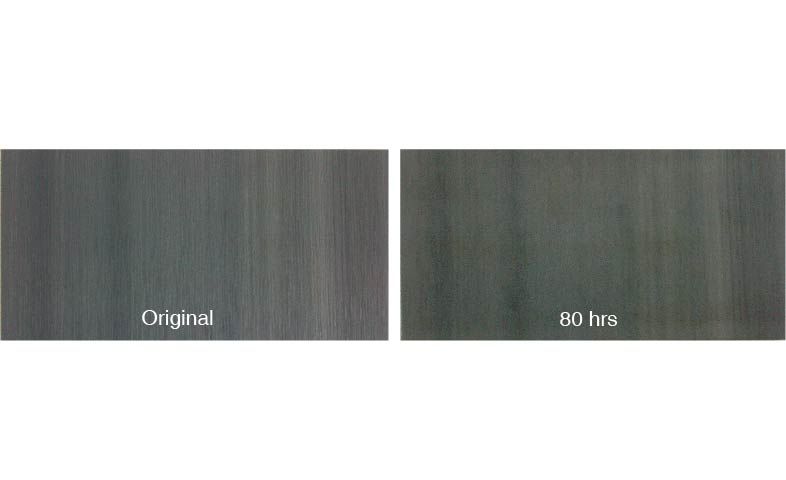

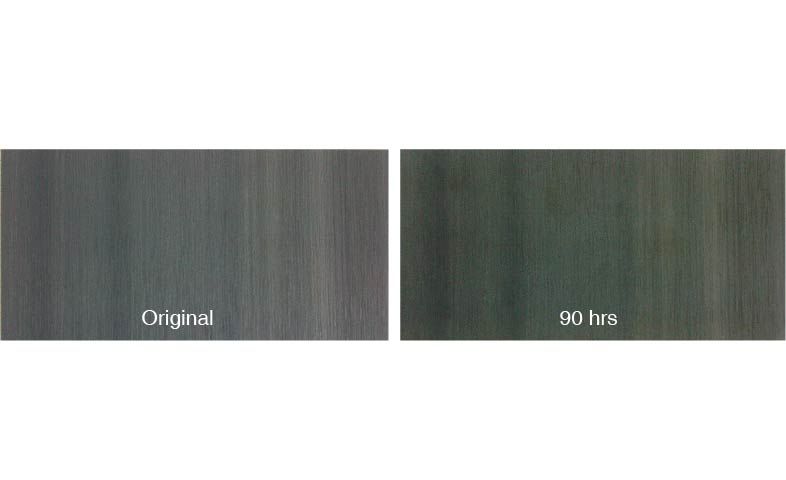

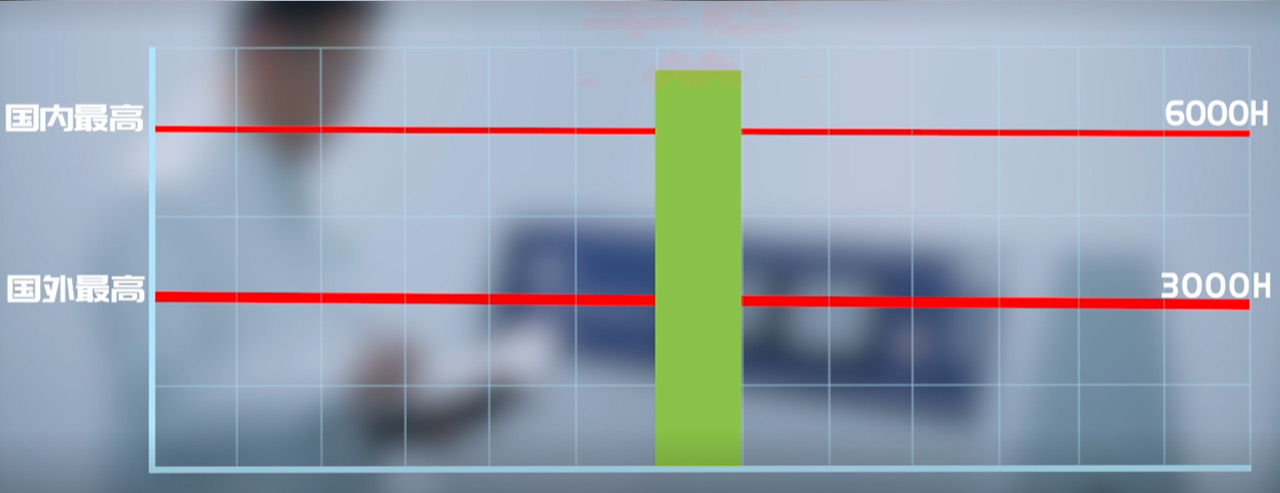

Quick Ultraviolet Aging Test

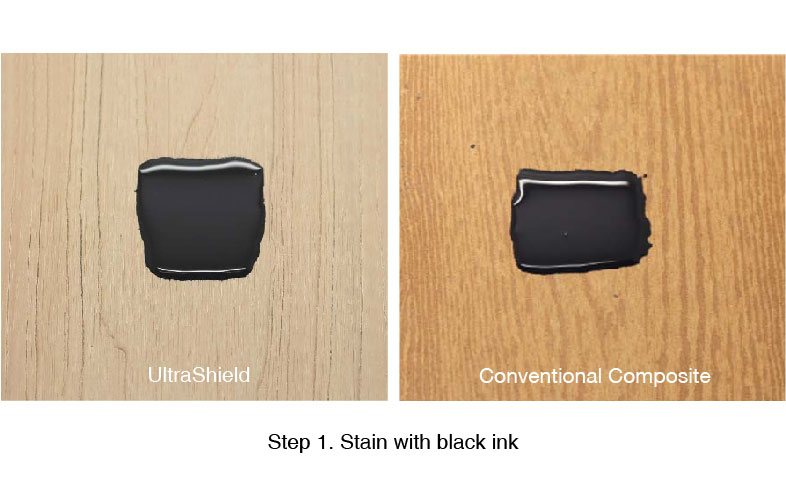

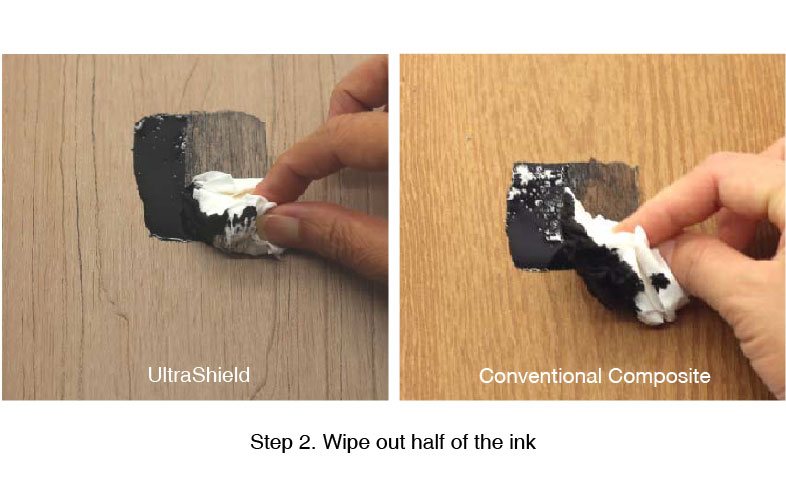

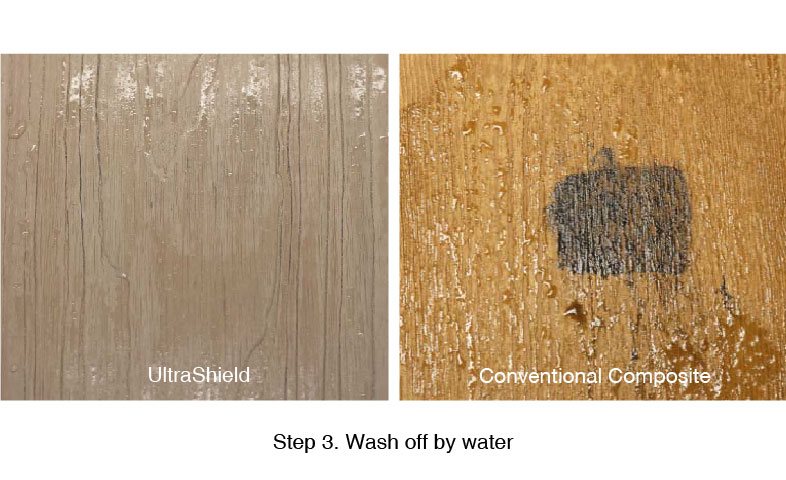

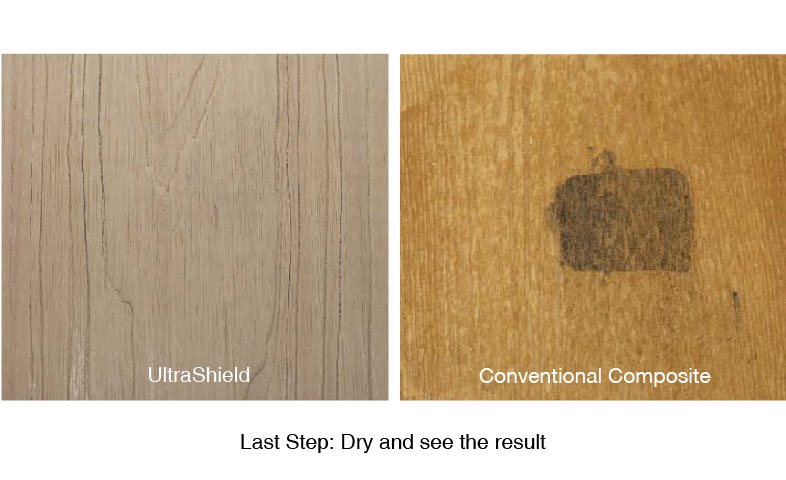

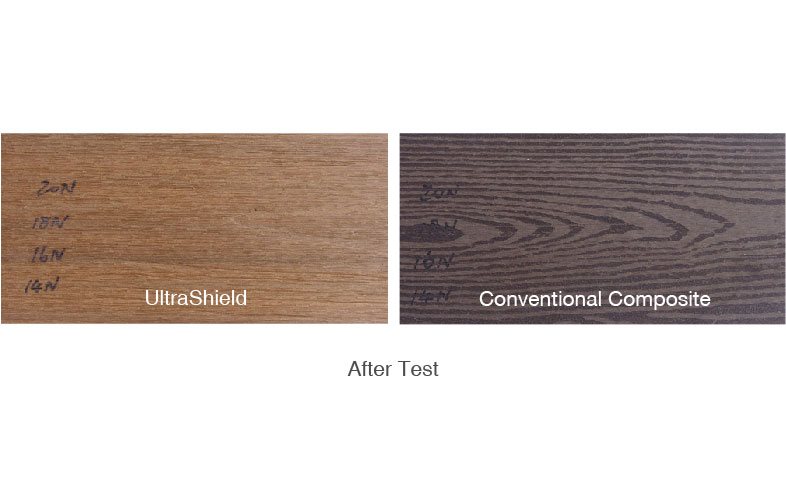

Scratch Resistance Test

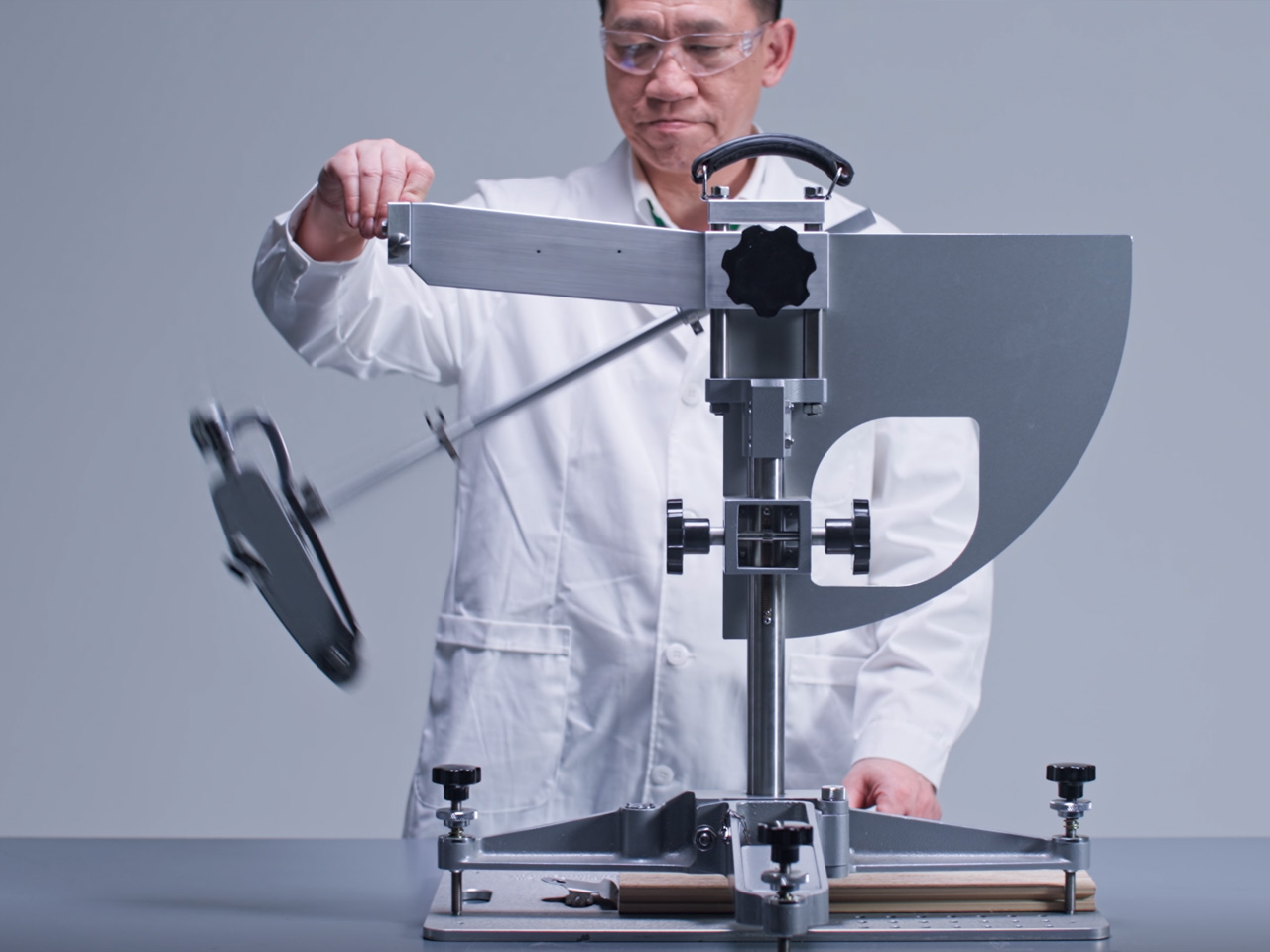

Pendulum Slip-Resistance Test

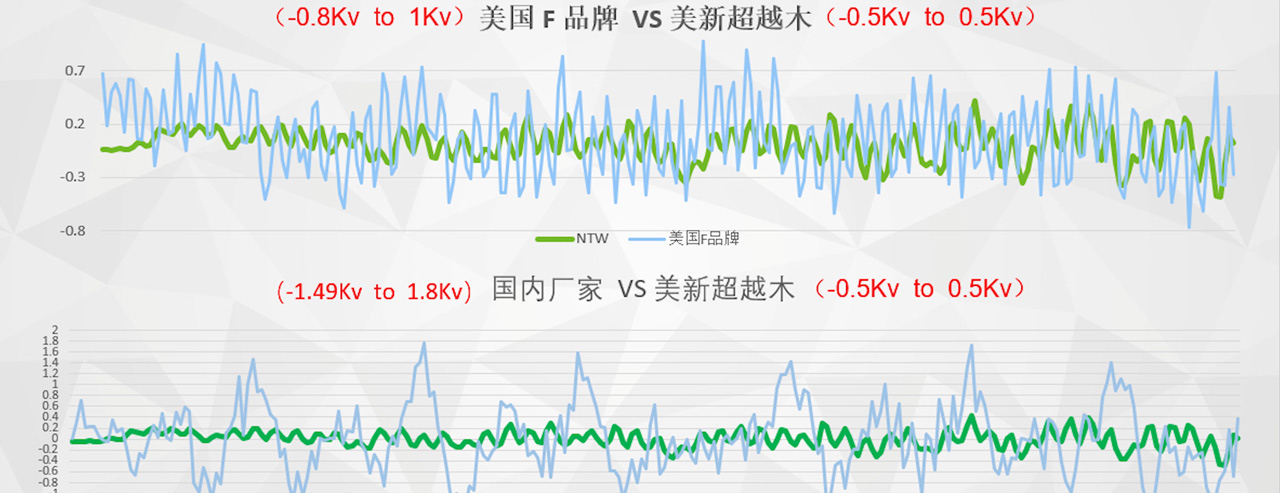

Human Walking Voltage Test

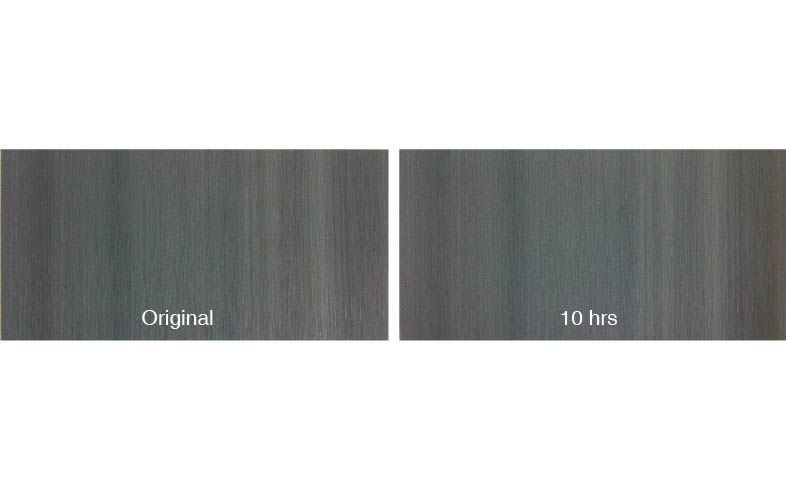

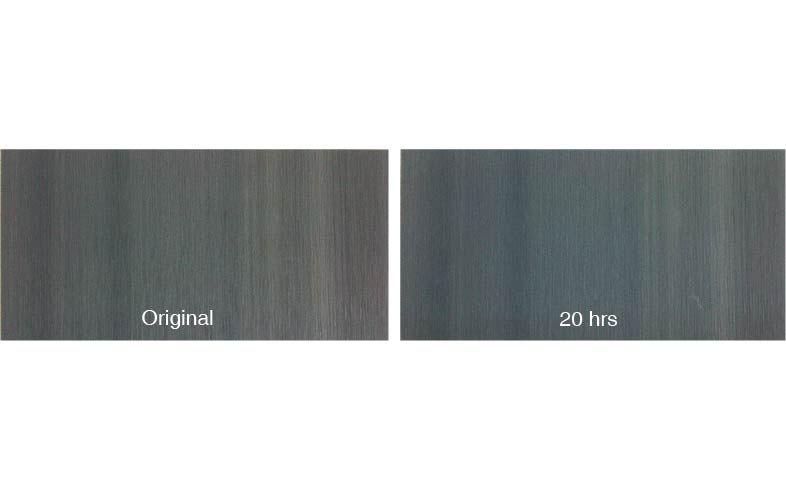

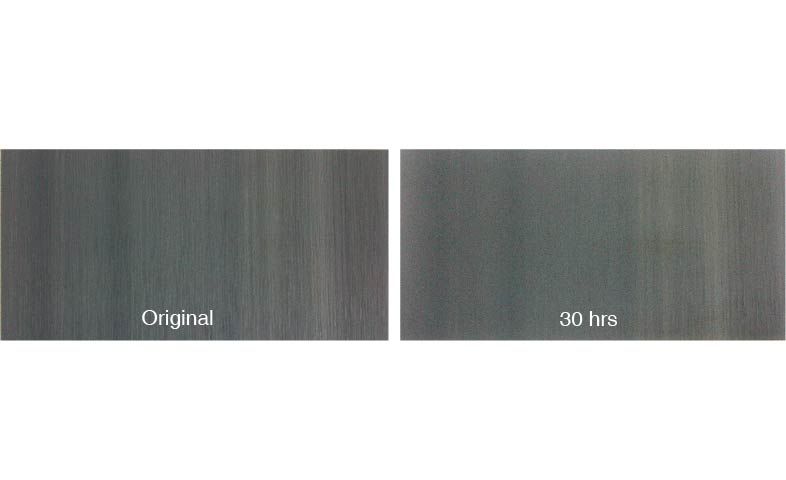

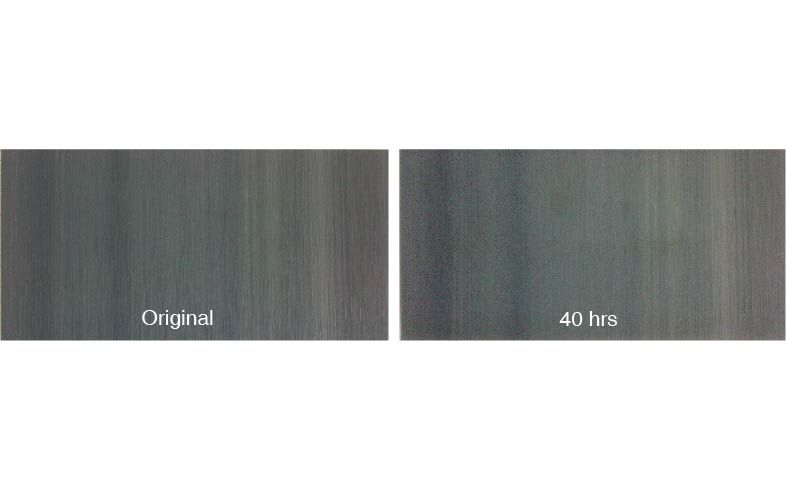

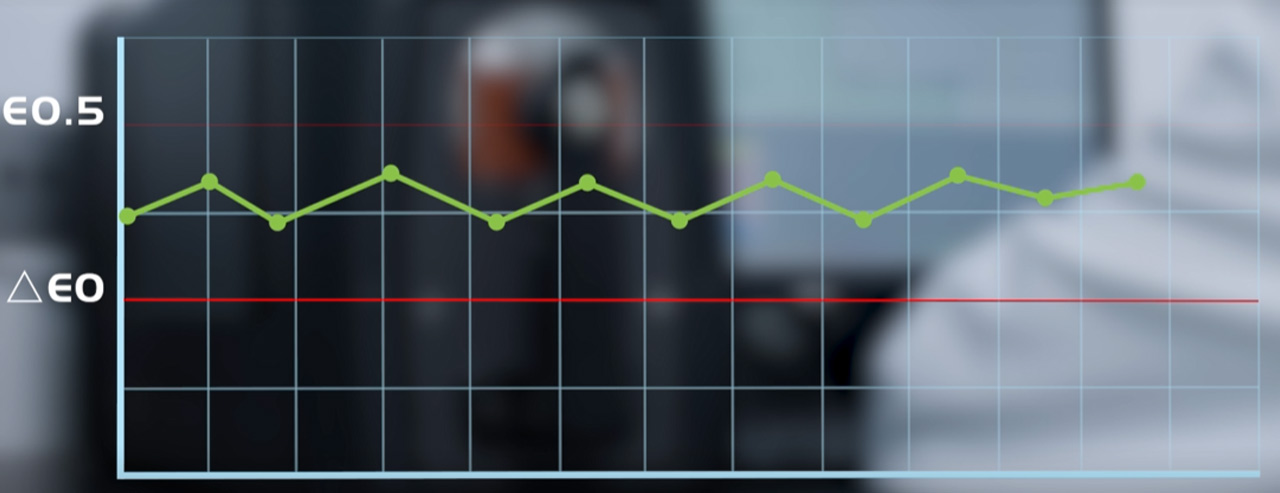

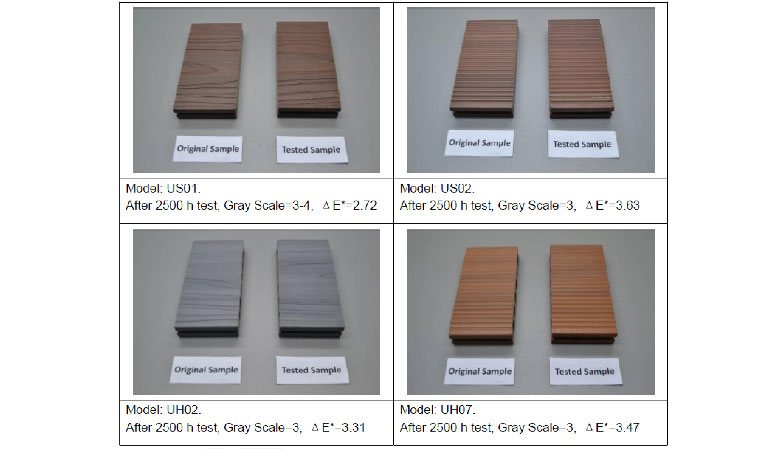

Chromatic Aberration Test

Boiling Test

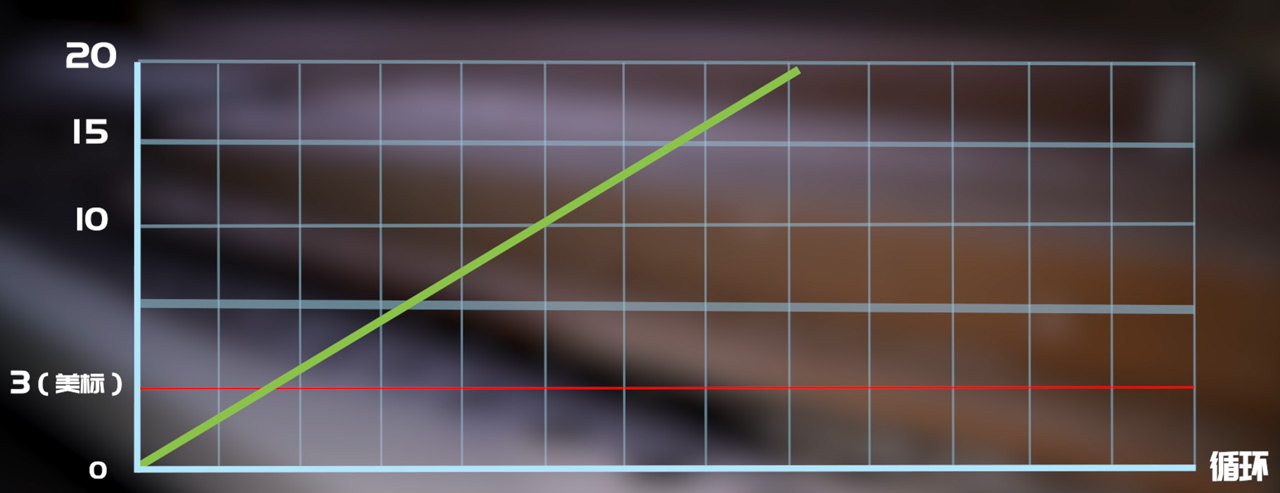

Freeze-Thaw Cycle Test

Falling Mass Impact Resistance Test

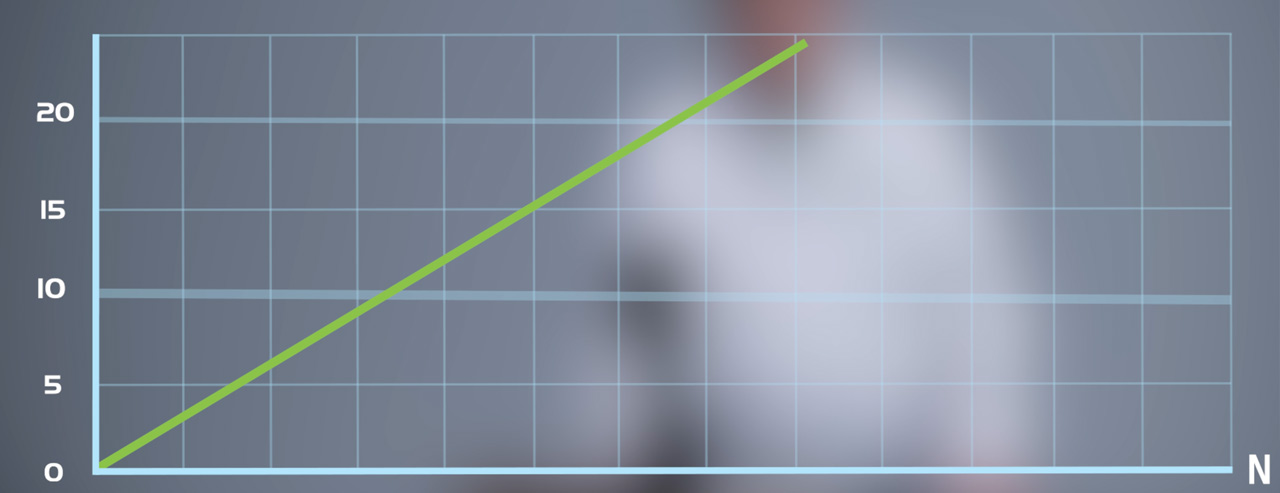

UltraShield: At 20N no obvious marks appear

Conventional Composite: At 8N marks appear

● Using a 1 mm needle to mark the composite

● Testing done under 8N-20N of pressure

● Testing Standard used: FLTM BO 162-01

After 1000 turns 81mg of material was worn off of the Conventional Composite

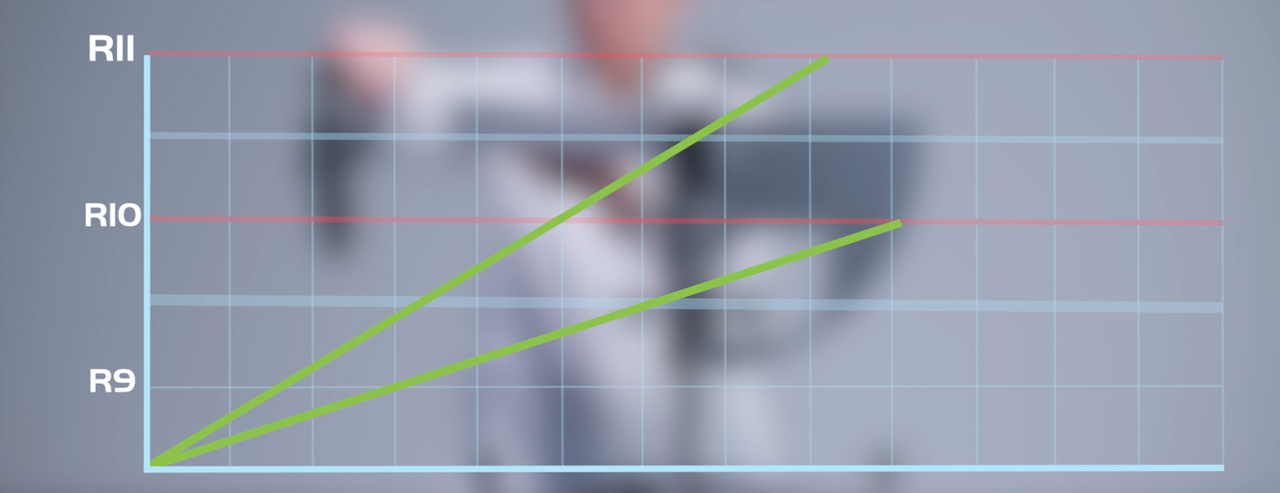

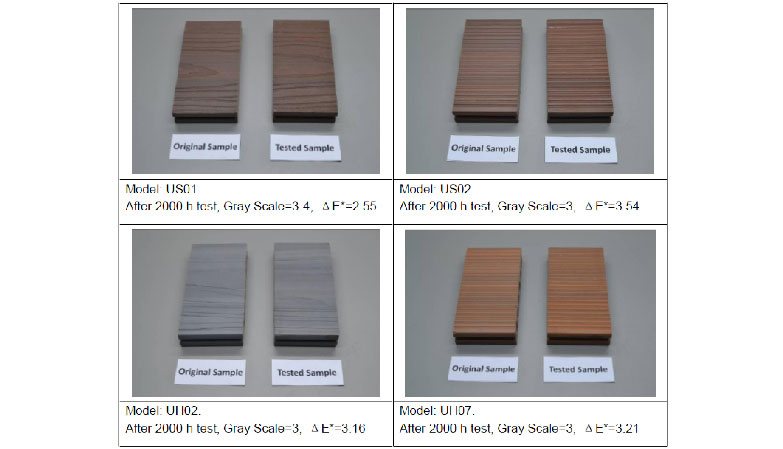

Experts say no visible color can be observed at a Delta E < 0.5.

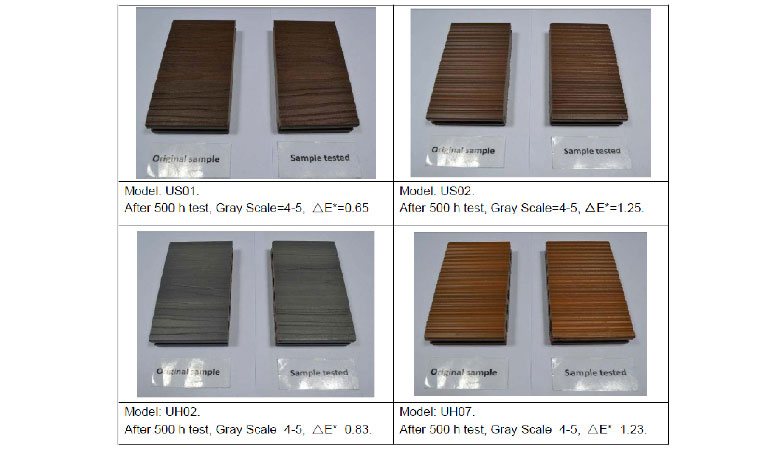

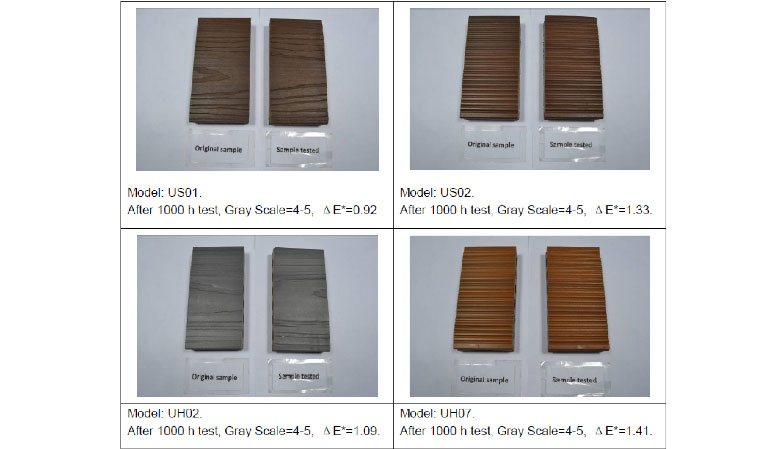

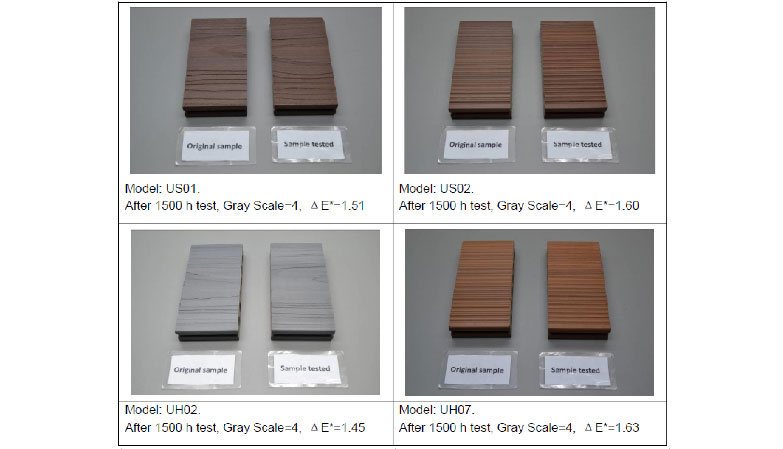

● Observations and recordings were taken every 500 hours

The results show no separation between the cap layer and the core, no damage, and no cracking.